Wrist Rehabilitation Device

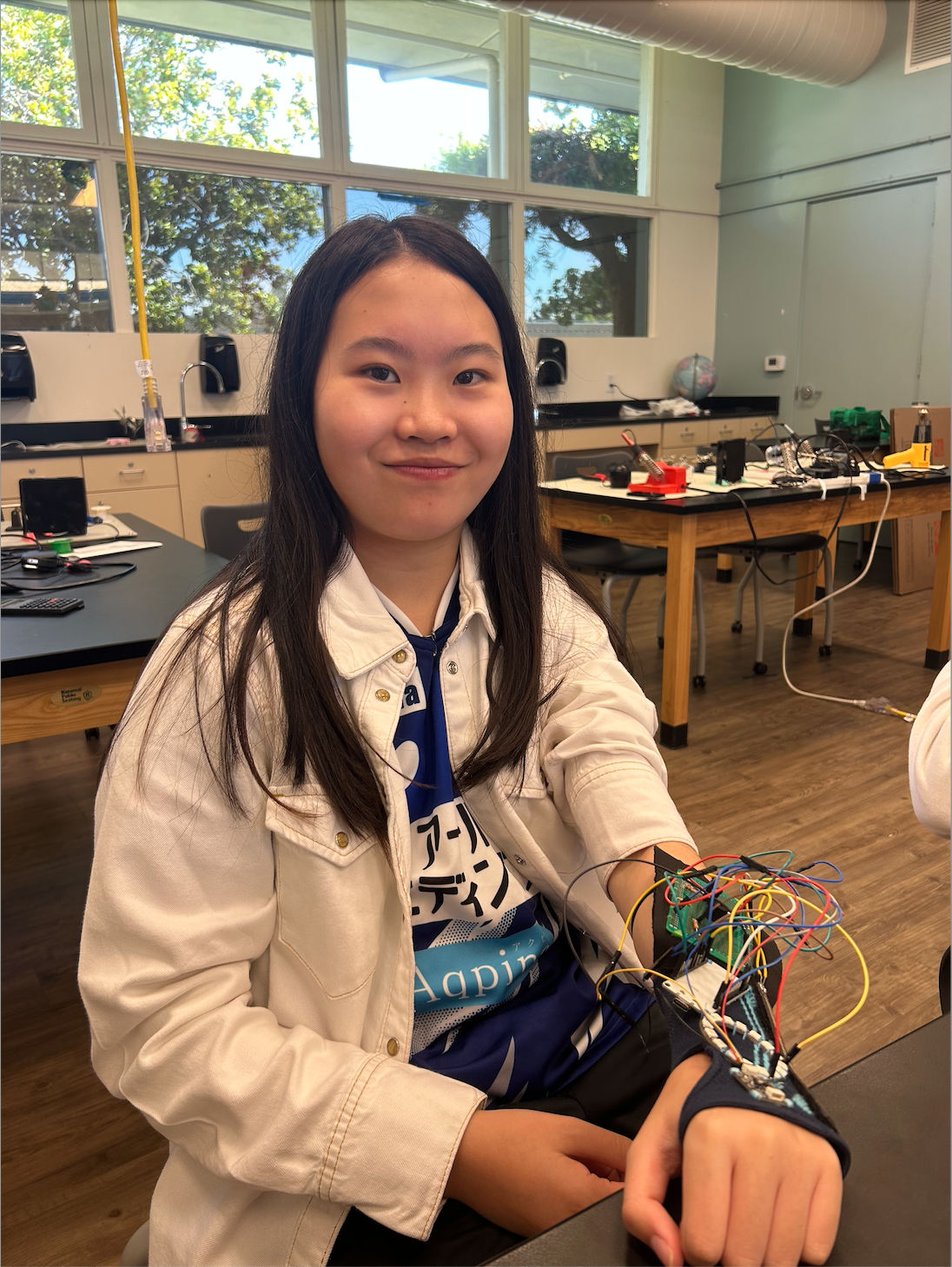

This is a device to help with wrist rehabilitation. It is a user command controlled device with sensors that can monitor the angle of the user’s wrist and can also help the user exercise by tracking wrist turns. The device uses both light and sound to alert the user of improper form and to monitor the number of wrist turns, helping ensure a smoother and more effective rehab process.

| Engineer | School | Area of Interest | Grade |

|---|---|---|---|

| Danica H | Monta Vista High School | Electrical Engineering | Incoming Junior |

Modification

Description

For my modification, I added a 16 bit Neopixel LED ring to my device. I coded it so that it could light up for different purposes, such as the front half of it lighting up red when my wrist is tilted downwards too much. I also implemented the rainbow function that exists in the library, letting it light up rainbow once my goal of wrist turns is reached. Besides adding an LED ring, I also added a command on my phone which lets me calibrate my own values for my flex sensor to use as the parameters of the map() function.

Adafruit 16 Bit Neopixel LED Ring

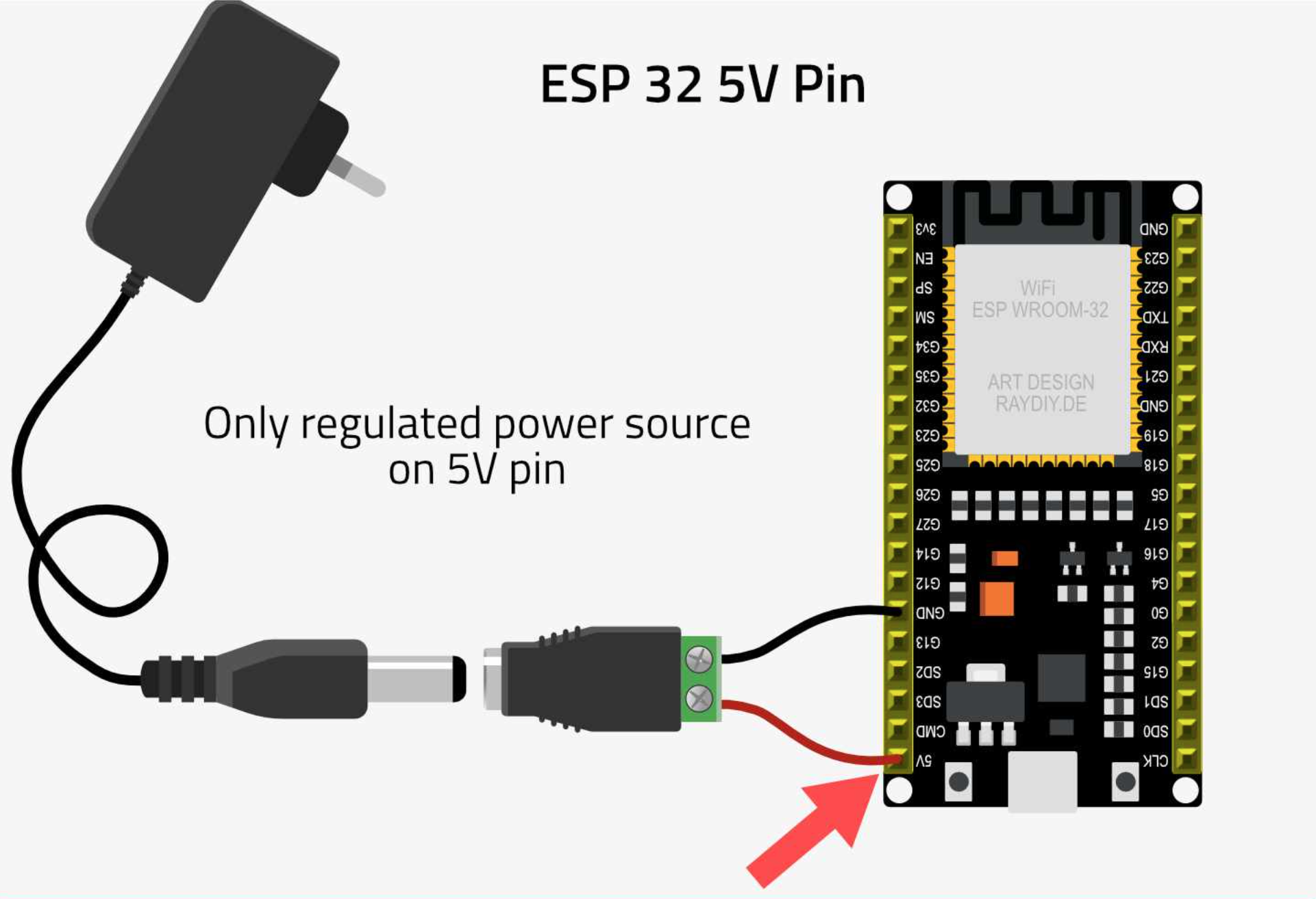

How the ring works is that it is an output device, so I have to connect my ESP32 to the D-in pin on the ring to allow data to come through. Also, for it to work, I have to tell it what to do in my code, using functions from the Adafruit_Neopixel library. The ring has 16 bits, or 16 lights, and I can code each of them can light up as different color at the same time. It needs 5V voltage as its power, so I ended up connecting it to the V-in pin on the ESP32. The ESP32 usually trasmits 3.3V as its max, but it’s because the board alters the voltage it receives from the computer and the USB-C cable. The V-in pin is an exception, so it allows whatever it is connecting to to directly tap into 5V without allowing the ESP32 to lower the voltage.

Figure #1: The V-in pin on the ESP32 that I connected the LED ring to

Figure #1: The V-in pin on the ESP32 that I connected the LED ring to

Calibrating the Flex Sensor

Even though I had apparently fixed the threshold of my resistance values in my third milestone, every time I sewed something onto my wrist sleeve, the values my flex sensor outputted would fluctuate a lot, and I would have to change the parameters of my map() function. Eventually, I decided that since the values were different every time I tested it, I would calibrate the values at the start of my code so I didn’t have to manually fix the parameters every time. I first made a boolean called flexCalibrate which would only be set to true during the first loop of my code. This would allow me to only calibrate my flex sensor when I first start using it. Then, I created a for loop to run 50 times while I straightened my wrist, which will measure the resistance each time (using the same equations I used in milestone 1) and add it to a variable called total. After the for loop, I divided the total by 50 to find the average, which will be used as the corresponding resistance value for 0 degrees. I then set total back to 0, and repeated the code process but with me holding my wrist at a 40 degree angle and the average being the corresponding value for 40 degrees. Since usually injured users wouldn’t be able to bend their wrist at 90 degrees, I changed the 90 degree parameter to be 40 instead. After the two for loops are done running, I set the two parameters in the map() function to be those two averages.

Figure #2: The new map function, map1 is the average of the 0 degree resistances, and map2 is the average of the 40 degree resistances

Challenges

The first challenge that I had was when I first started working with the LED ring. The ring has two pins, D-in and D-out. But, because the pins on the ring look like DO and DI, I thought it meant D1 and D0 and I could connect the ESP32 to any of those pins. However, the ring is an output device, so I have to plug it in the DI pin for it to take in data and do what it’s supposed to. I kept plugging it in the DO pin, so the ring wouldn’t light up no matter what I wrote in my code. Once I realized it meant D-in and D-out and I connected the wires correctly, the ring started working. The second challenge was after I soldered all of my sensors and wires onto the PCB board. Both the flex sensor and the LED ring stopped working completely. The flex sensor was giving me unrealistic values and the ring was turning on. The first problem was that I had apparently gotten a bit of solder on the LED ring, so I had to solder on a new one. I thought I fixed the problem, but it also stopped working after I soldered it on. I ended up realizing that the problem was the two power lines and the two ground lines of the opposite sides of the PCB board aren’t connected by default, so my sensors weren’t getting the power they needed. As shown in figure #4 below, I had to manually connect the two sides with two wires connectors (basically small jumper wires). After I did that, my flex sensor and my LED ring started working properly.

Figure #3: The D-in and D-out pins on the led ring

Figure #4: The PCB board with two wires connecting the power lines and ground lines

Next Steps

If I had more time, I would probably improve the precision of my accelerometer when monitoring wrist turns. Right now, I only monitor when I go down and when I go up, but not when I go left and right. I want to make it so that it monitors when I go in all 4 directions, that way I can’t cheat and just move my wrist up and down. I could also try to implement speech into my project, and tell the device what to do instead of using commands on my phone.

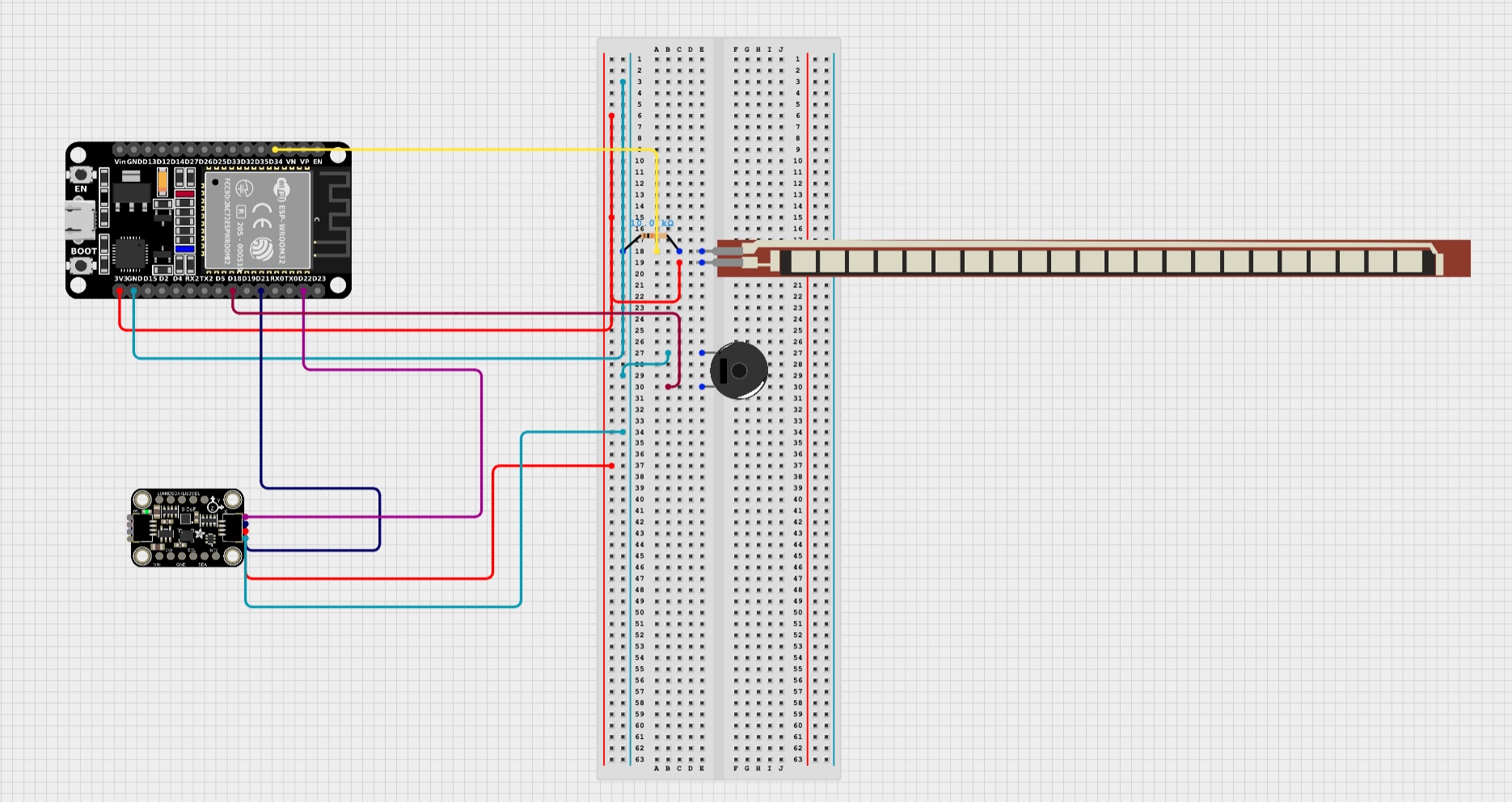

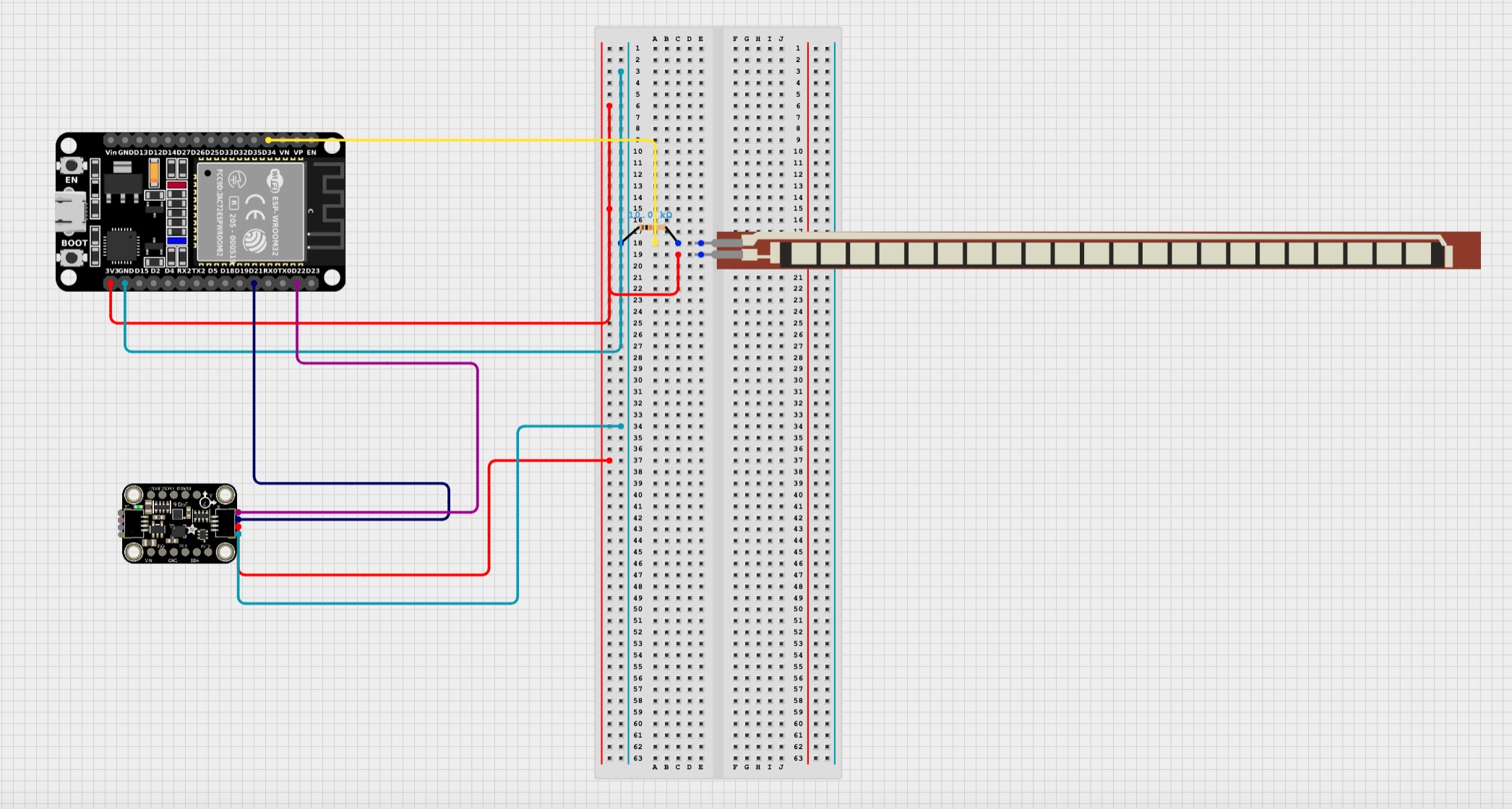

Schematic

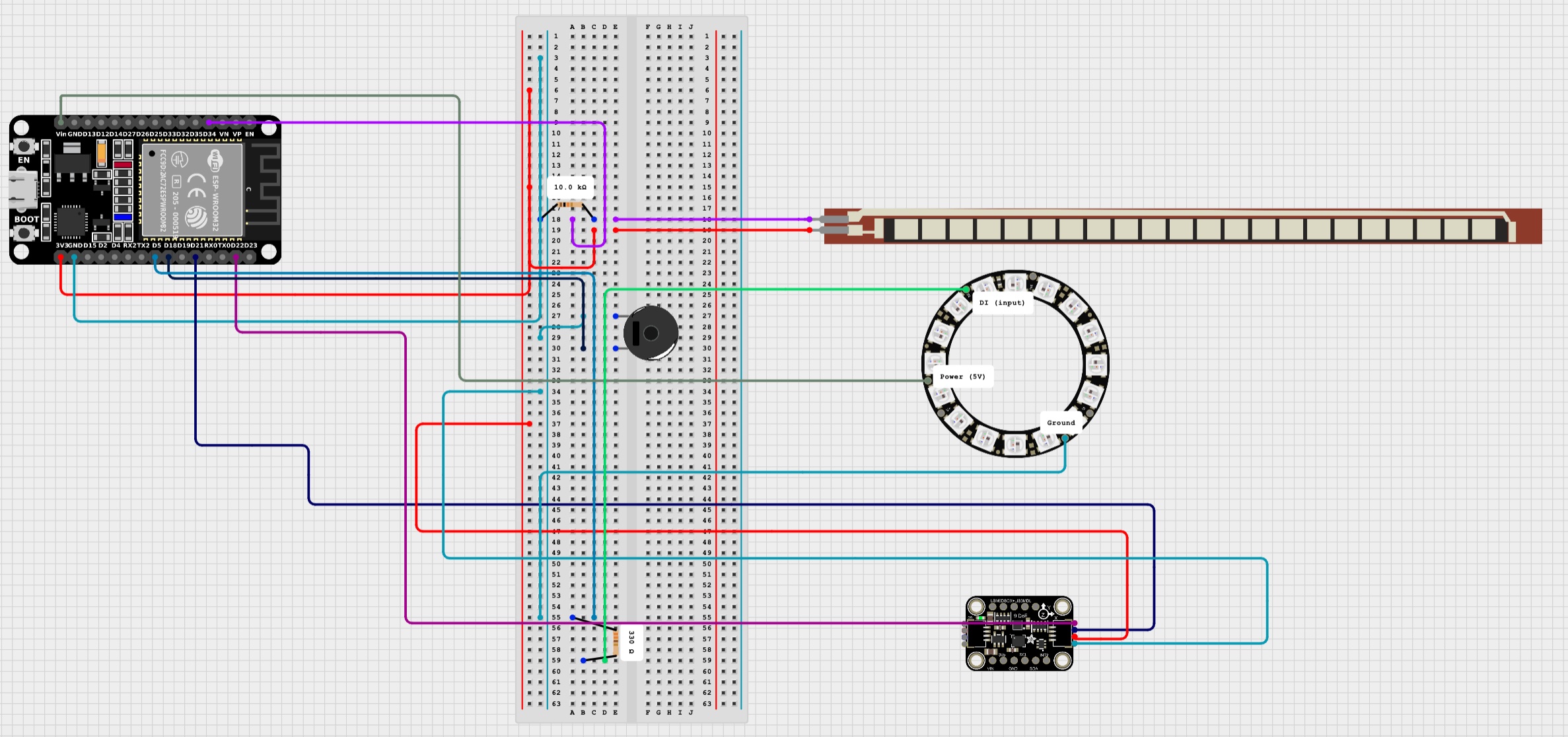

Figure #5: Schematic for flex sensor, accelerometer, piezo buzzer, and LED ring

Figure #5: Schematic for flex sensor, accelerometer, piezo buzzer, and LED ring

Final Milestone

Description

For my third milestone, I soldered my flex sensor onto two wires so that it didn’t have to be stuck to the breadbaord for it to work. When I was soldering though, I accidentally broke one of the metal legs off the sensor, so I had directly solder the jumper wire on the metal base instead of soldering the leg to the wire. Luckily, it still works the same and transfers electrical current smoothly. After I soldered it, I stuck it to the adhesive side of a piece of velcro and then attached the velcro to my compression sleeve. I also sewed my accelerometer onto my sleeve, and I added a 220 ohm resistor to my piezo buzzer to reduce the volume a bit.

Figure #6: The sensor velcroed on the wrist sleeve and the accelerometer also sewed on

Challenges

The main challenges I had were after I soldered the flex sensor. For some reason, when I tested it, my angle values started to jump a lot, sometimes randomly shooting to really high values and sometimes decreasing to -67 degrees. When I debugged it, I noticed the flex value was going up to 4095.0, which is the maximum digital value the flex sensor can output. That meant there was a short somewhere, which means that power is connecting to ground. After looking at my soldering, I realized one of the copper strands of the jumper wire was touching one of the metal pins on the back of the flex sensor which was causing the flex sensor to output really extreme values. After I removed the strand, the flex sensor stopped outputing extremely fluctuating values. But, the angles were still wrong. For example, when my wrist was straight, the angle outputed was about 20 degrees. I concluded that the threshold for the map() function needed to be changed, because maybe the velcro caused the sensor to bend weirdly. As shown in the figure below, the circled parameters are the threshold, with 15000 corresponding to 0 degrees and 45000 resistance corresponding to 90 degrees. After I tweaked the parameters for the map() function, everything started working normally.

Figure #7: The map function that converts resistance to angle

Next Steps

I’m going to start thinking of what modifications I can add to my device, and start soldering everything to my PCB board. I’ll also sew my ESP32 onto my wrist sleeve.

Schematic

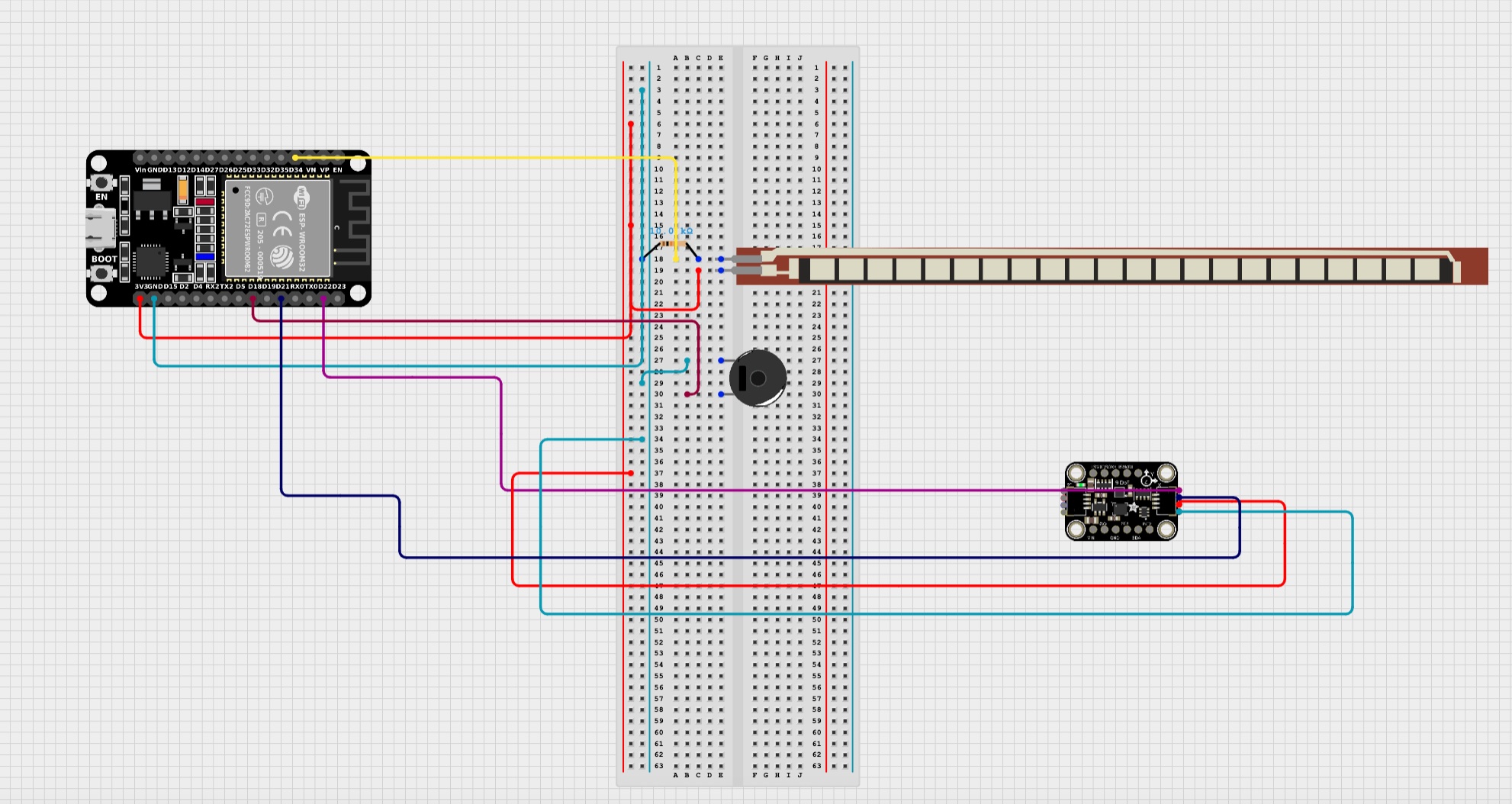

Figure #8: Schematic of flex sensor, accelerometer, piezo buzzer

Figure #8: Schematic of flex sensor, accelerometer, piezo buzzer

Second Milestone

Description

For my second milestone, I actually changed the function of my accelerometer. Since my flex sensor already functions to monitor the angle of my wrist, I coded it to help monitor the number of wrist turns you do. I also added a piezo buzzer onto my board so it can beep for different purposes. Finally, I incoporated the Bluetooth module that’s built on the ESP32 so I can wirelessly transmit information from my phone to the computer and the Arduino. Using the Bluetooth, I added commands that I can type out on my phone to tell the device to do something. (Refer to the milestone 2 code or milestone 3 in the code appendix to see how I coded the commands)

Figure #9: The commands I can type on my phone

Piezo Buzzer

The piezo buzzer is an output device, so I tell it what to do in my code. I can control when it beeps, the frequency at which it beeps at, and how long it beeps for. Since I want the buzzer to beep for 3 different purposes, I set a different frequency each time so the user wouldn’t be confused on what it’s beeping about. For example, if the flex sensor bends past 30 degrees (the threshold I set), it will keep beeping at 1000 Hz until the flex sensor’s angle is below 30. On the other hand, if I’m doing wrist turns, the piezo buzzer will beep at 3000 Hz for 500 milliseconds every time I complete a wrist turn.

How to Monitor Wrist Turns

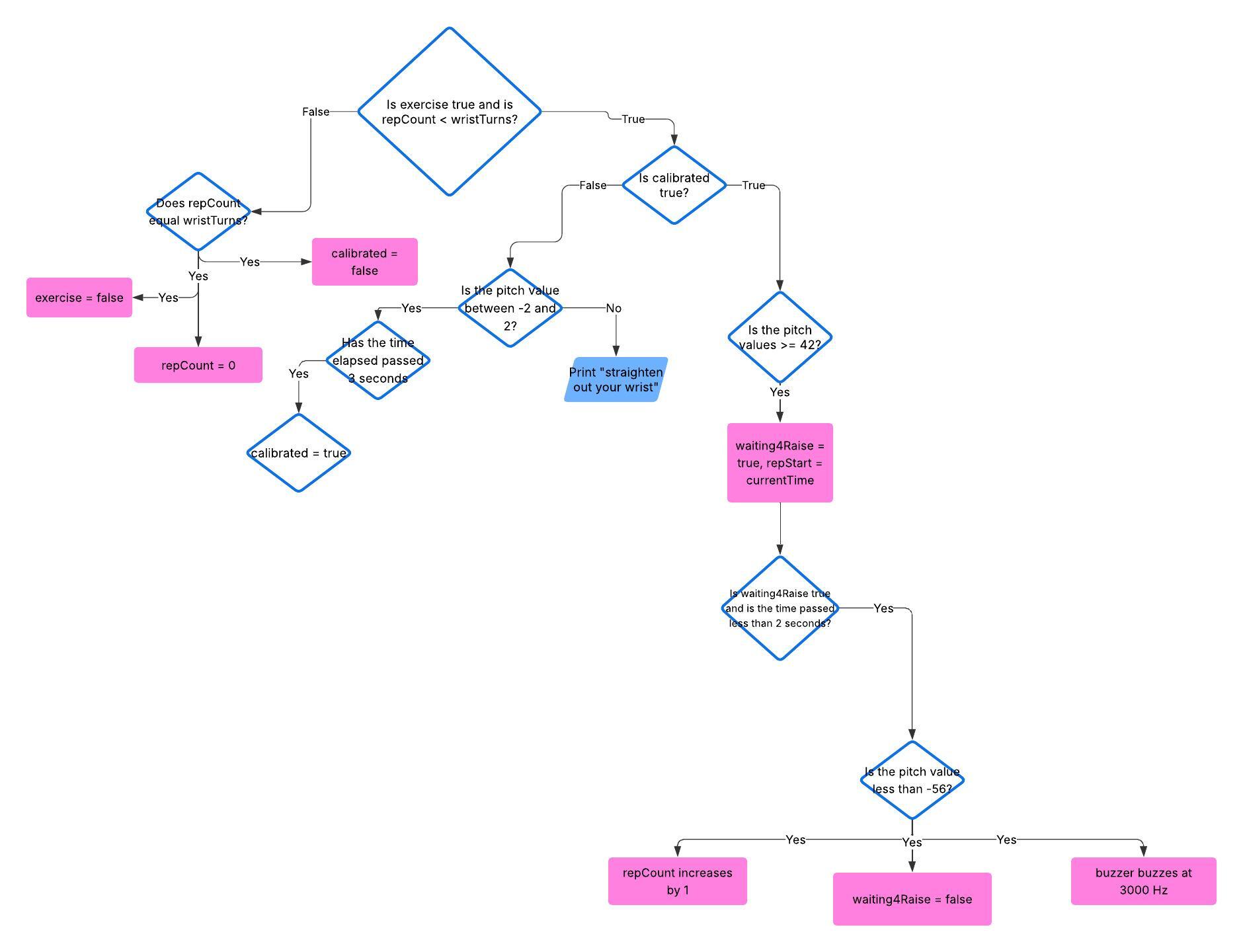

For the accelerometer, I really didn’t change much. I still used the Madgwick filter to convert the values of the gyroscope and the accelerometer into orientations along the roll, pitch, and yaw axes. The only difference was how I used the values along the pitch axes. The code I had to write had a lot of checks and I had to make many global variables. For starters, I needed to make sure that the code block for wrist turns would only run when I commanded it to. I made a boolean called exercise and made it so the code block would only run if exercise was set to true. Next, I made a boolean called calibrated. To make it true, I have to make sure my wrist is straight and the pitch values were between 2 and -2 for at least 3 seconds. Once the device is calibrated, I can start doing my wrist turns. For my wrist turns, I made an another boolean called waiting4Raise. Once my wrist is pointed downwards and has a pitch value that is bigger than 42, waiting4Raise becomes true and a timer starts. waiting4Raise basically means that the device is waiting for me to move my wrist upward, since I already moved it down. If within 2 seconds my wrist is pointed up and the pitch value is less than -56, the rep count increases since that counts as a complete wrist turn. After one wrist turn, waiting4Raise is set back to false. If I have completed all of my wrist turns, exercise is set to false, calibrated is also set to false, and the rep count is set back to 0. (Refer to the second or third milestone code in the code appendix to see how I coded the wrist turns)

Figure #10: The flow chart of my wrist turn code

Figure #10: The flow chart of my wrist turn code

Bluetooth

Since the ESP32 already has a built in Bluetooth module, I didn’t have to use the HC05. Implementing the Bluetooth module was not too complicated. I first downloaded the BleSerial library on Arduino and created a BleSerial object in my code. The BleSerial object is the serial on my phone, and creating it allows me to actually run code that uses it. I then downloaded the BLESerialnRF52 app on my phone, since downloading an app is the only way to open a serial on a phone. I then figured out how to communicate between the two serials using code. It mainly consisted of using the available() function to check if there was data to be read, then using the read() function to read the data. Then with that data I could do whatever I wanted. I realized I could use this communication to write commands on my phone. I tweaked the code so that the device would do things based on the commands I typed on my phone serial. For example, if I typed “start monitoring” on my phone, the device would start monitoring the angle of the flex sensor and allowing the buzzer to beep. Or, if I wanted to do a certain amount of wrist turns, I could type in “do wrist turns” on my serial and also type in how many I want to do. (Refer to the milestone 2 or milestone 2 code in the code appendix to see how I coded the bluetooth serial)

Figure #11: The BLESerialnRF52 app and ESP32

Figure #11: The BLESerialnRF52 app and ESP32

Challenges

One of my challenges was that for some reason, when I was first testing my accelerometer for the wrist turns, the Madgwick filter was updating really slowly even though the frequency it was updating at was already really fast. I even tried upping the frequency, but that didn’t change anything. Some time later, the code stopped uploading entirely and my serial port disappeared from my board menu in Arduino even though everything was plugged in. After trying to restart my computer and the Arduino app, I unplugged my device from the first charging port on my computer and plugged it into the second charging port. That charging port probably allowed more connection with the board, because once I plugged it into that port, the serial port showed up again and allowed me to upload code. My accelerometer also started updating at the correct speed when I uploaded my code. The second challenge that I had was when I tried to use the toLowerCase() method in my code. The toLowerCase() method is a void function, which means it doesn’t return anything when I call it. But, since in Java though it returns a string, I assumed it was the same in C++. I basically tried to set a variable to nothing, so the code kept giving me errors. I realized that the method updates the string itself, so I needed to first call the method, and then set the variable to that updated string. The third challenge I had was with the write() function when working with the phone and computer serials. The write() function is the print() method, except it converts ASCII values to actual text when it prints. But, write() didn’t work for the phone serial, only print() worked. To fix it, instead of using the read() function when reading in data, I used the readStringUntil() function, which automatically returns the string in its text form. Then I just printed that string onto the phone serial.

Next Steps

For my next milestone, I will probably start sewing sensors and wires onto my compression sleeve. I’ll also start soldering everything to my PCB board so I don’t have to use my breadboard anymore.

Schematic

Figure #12: Schematic for flex sensor, accelerometer, and piezo buzzer

Figure #12: Schematic for flex sensor, accelerometer, and piezo buzzer

First Milestone

Description

For my first milestone, I figured out how to code and wire both the flex sensor and the accelerometer and make them detect when an angle is bad for my wrist. I coded both of them to tell me if I bended my wrist too far back or too far forward.

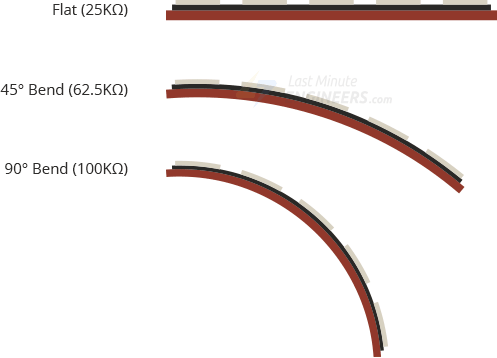

Flex Sensor

The flex sensor is a resistor, and the more it bends the more resistance it will apply. I coded it so that the bend corresponds to the angle of the wrist, so the more it bends, the more the angle increases. It doesn’t originally send data as angles though, it sends data as analog data (information sensors send represented by a range of values). I had to attach it to a pin that would convert the data to understandable digital data (values that actually follow Arduino’s documentation). This process is basically ADC conversion. But, since I wanted the data to be in degrees, I then had to use a few equations to convert the digital data in degrees.

Figure #13: Flex sensor

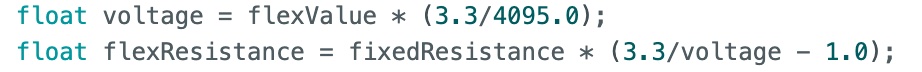

Converting Digital Data to Angles

The first equation I used was (flexValue * (3.3/4095.0)). FlexValue is the digital data that the Arduino outputs, 3.3 is the max analog value (aka voltage) the ESP32 is able to output, and 4095.0 is the corresponding max digital value. This equation helps convert the digital data to voltage. The next equation I used was (10000 * (3.3/voltage - 1.0)). The 10000 is the resistance of the flex sensor when it is straight, the 3.3 is again the max value of voltage the ESP32 can output, and the voltage is the voltage found from the previous equation. The equation is used to convert the voltage to the amount of resistance the flex sensor is applying. After I used those 2 equations to find the resistance, I used a function called map() that actually helps convert those resistance values into angles. The map() function takes in a few parameters so know what resistance value counts as 0 degrees and what counts as 90 degrees. I set the optimal wrist degree to 30 degrees, which means if the flex sensor ever bends past 30 degrees the computer will print out a message warning me to fix my wrist posture.

Figure #14: Equations that I used

Figure #14: Equations that I used

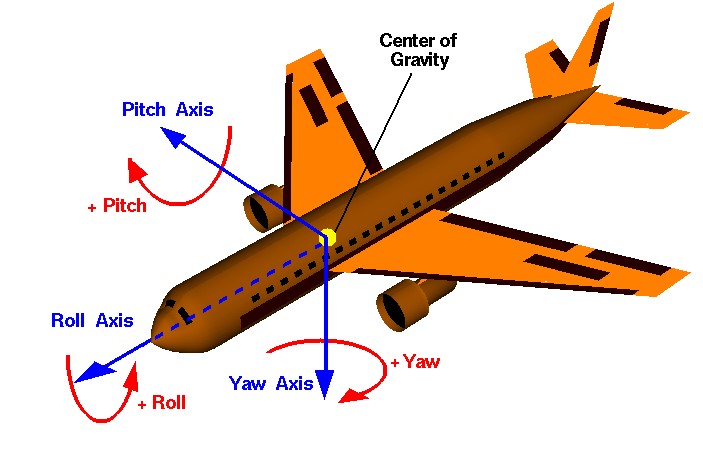

Accelerometer and Madgwick Filter

For the accelerometer, since it measures both values of a gyroscope (rotation speed) and an accelerometer (acceleration) along the x, y, and z axes, it outputs 6 values at a time. I ended up using a Madgwick filter to help convert all of those values into the orientationos of the object along the roll, yaw, and pitch axes. The roll, pitch, and yaw axes are the main axes that planes use in the air. I again set a threshold for the pitch axis, since the pitch axis is what the wrist technically rotates around. That threshold will also indicate if I need to fix my posture.

Figure #15: Roll, pitch, and yaw axes

Challenges

One of the challenges was I had was adjusting the conversion equations. The ones I found online were for the Arduino Uno board, and since I’m using the ESP32 board, the equations were giving me the wrong values. The voltage was 5 instead of 3.3, and the corresponding digital was 1023.0 instead of 4095.0. I had to adjust those values according to the ranges of the ESP32. But after I adjusted the values, another problem happened. As I bent the flex sensor, the output values would get smaller instead of larger. After analyzing the equations, I concluded I needed to switch the positions of my resistor and my flex sensor on my breadboard, as the way I had originally placed them caused them to send incorrect values to the equation. Another challenge was that the accelerometer also had a gyroscope, so it was giving me 6 values at a time and I didn’t know which of the 6 to use. I realized that Arduino has a library called Madgwick that actually filters those 6 values and gives you the position of the accelerometer along the roll, yaw, and pitch axes. I ended up using that filter and using the values it gave me to set a threshold.

Next Steps

For my next steps, I will first add a piezo buzzer to my ESP32 so that it will buzz whenever my wrist is too bent. I will also try and incorporate Bluetooth into my project so that the device can wirelessly transmit data to the computer.

Schematic

Figure #16: Schematic for flex sensor and accelerometer

Figure #16: Schematic for flex sensor and accelerometer

Code

Final Code

// Basic demo for accelerometer/gyro readings from Adafruit LSM6DS3TR-C

const int flexPin = A6;

const int fixedResistance = 10000;

const int buzzer = 18;

const int ledPins[8] = {13, 14, 15, 0, 1, 2, 3, 4};

unsigned long currentTime = millis();

unsigned long repStart = 0.0;

int map1 = 0;

int map2 = 0;

int repCount = 0;

int wristTurns = 1;

int countSeconds = 0;

int pinCounter = 0;

bool flexCalibrate = false;

bool waiting4Raise = false;

bool calibrated = false;

bool monitor = false;

bool exercise = false;

#include <MadgwickAHRS.h>

#include <Adafruit_LSM6DS3TRC.h>

#include <BleSerial.h>

#include <Adafruit_NeoPixel.h>

// For SPI mode, we need a CS pin

#define LSM_CS 10

// For software-SPI mode we need SCK/MOSI/MISO pins

#define LSM_SCK 13

#define LSM_MISO 12

#define LSM_MOSI 11

#define LED_PIN 5

#define LED_COUNT 16

Adafruit_NeoPixel ring(LED_COUNT, LED_PIN, NEO_GRB + NEO_KHZ800);

Adafruit_LSM6DS3TRC lsm6ds3trc;

Madgwick filter;

BleSerial ble;

const float sampleFreq = 20.0;

void setup() {

Serial.begin(115200);

filter.begin(sampleFreq);

ble.begin("danica's serial");

ring.begin();

ring.show();

ring.setBrightness(50);

while (!Serial)

delay(10); // will pause Zero, Leonardo, etc until serial console opens

Serial.println("Adafruit LSM6DS3TR-C test!");

ble.println("type menu to see list of commands available");

if (!lsm6ds3trc.begin_I2C()) {

// if (!lsm6ds3trc.begin_SPI(LSM_CS)) {

// if (!lsm6ds3trc.begin_SPI(LSM_CS, LSM_SCK, LSM_MISO, LSM_MOSI)) {

Serial.println("Failed to find LSM6DS3TR-C chip");

while (1) {

delay(10);

}

}

Serial.println("LSM6DS3TR-C Found!");

// lsm6ds3trc.setAccelRange(LSM6DS_ACCEL_RANGE_2_G);

Serial.print("Accelerometer range set to: ");

switch (lsm6ds3trc.getAccelRange()) {

case LSM6DS_ACCEL_RANGE_2_G:

Serial.println("+-2G");

break;

case LSM6DS_ACCEL_RANGE_4_G:

Serial.println("+-4G");

break;

case LSM6DS_ACCEL_RANGE_8_G:

Serial.println("+-8G");

break;

case LSM6DS_ACCEL_RANGE_16_G:

Serial.println("+-16G");

break;

}

// lsm6ds3trc.setGyroRange(LSM6DS_GYRO_RANGE_250_DPS);

Serial.print("Gyro range set to: ");

switch (lsm6ds3trc.getGyroRange()) {

case LSM6DS_GYRO_RANGE_125_DPS:

Serial.println("125 degrees/s");

break;

case LSM6DS_GYRO_RANGE_250_DPS:

Serial.println("250 degrees/s");

break;

case LSM6DS_GYRO_RANGE_500_DPS:

Serial.println("500 degrees/s");

break;

case LSM6DS_GYRO_RANGE_1000_DPS:

Serial.println("1000 degrees/s");

break;

case LSM6DS_GYRO_RANGE_2000_DPS:

Serial.println("2000 degrees/s");

break;

case ISM330DHCX_GYRO_RANGE_4000_DPS:

break; // unsupported range for the DS33

}

//lsm6ds3trc.setAccelDataRate(LSM6DS_RATE_20_HZ);

Serial.print("Accelerometer data rate set to: ");

switch (lsm6ds3trc.getAccelDataRate()) {

case LSM6DS_RATE_SHUTDOWN:

Serial.println("0 Hz");

break;

case LSM6DS_RATE_12_5_HZ:

Serial.println("12.5 Hz");

break;

case LSM6DS_RATE_26_HZ:

Serial.println("26 Hz");

break;

case LSM6DS_RATE_52_HZ:

Serial.println("52 Hz");

break;

case LSM6DS_RATE_104_HZ:

Serial.println("104 Hz");

break;

case LSM6DS_RATE_208_HZ:

Serial.println("208 Hz");

break;

case LSM6DS_RATE_416_HZ:

Serial.println("416 Hz");

break;

case LSM6DS_RATE_833_HZ:

Serial.println("833 Hz");

break;

case LSM6DS_RATE_1_66K_HZ:

Serial.println("1.66 KHz");

break;

case LSM6DS_RATE_3_33K_HZ:

Serial.println("3.33 KHz");

break;

case LSM6DS_RATE_6_66K_HZ:

Serial.println("6.66 KHz");

break;

}

// lsm6ds3trc.setGyroDataRate(LSM6DS_RATE_12_5_HZ);

Serial.print("Gyro data rate set to: ");

switch (lsm6ds3trc.getGyroDataRate()) {

case LSM6DS_RATE_SHUTDOWN:

Serial.println("0 Hz");

break;

case LSM6DS_RATE_12_5_HZ:

Serial.println("12.5 Hz");

break;

case LSM6DS_RATE_26_HZ:

Serial.println("26 Hz");

break;

case LSM6DS_RATE_52_HZ:

Serial.println("52 Hz");

break;

case LSM6DS_RATE_104_HZ:

Serial.println("104 Hz");

break;

case LSM6DS_RATE_208_HZ:

Serial.println("208 Hz");

break;

case LSM6DS_RATE_416_HZ:

Serial.println("416 Hz");

break;

case LSM6DS_RATE_833_HZ:

Serial.println("833 Hz");

break;

case LSM6DS_RATE_1_66K_HZ:

Serial.println("1.66 KHz");

break;

case LSM6DS_RATE_3_33K_HZ:

Serial.println("3.33 KHz");

break;

case LSM6DS_RATE_6_66K_HZ:

Serial.println("6.66 KHz");

break;

}

lsm6ds3trc.configInt1(false, false, true); // accelerometer DRDY on INT1

lsm6ds3trc.configInt2(false, true, false); // gyro DRDY on INT2

pinMode(buzzer, OUTPUT);

}

void loop() {

// Get a new normalized sensor event

sensors_event_t accel;

sensors_event_t gyro;

sensors_event_t temp;

lsm6ds3trc.getEvent(&accel, &gyro, &temp);

// Serial.print("\t\tTemperature ");

// Serial.print(temp.temperature);

// Serial.println(" deg C");

/* Display the results (acceleration is measured in m/s^2) */

// Serial.print("\t\tAccel X: ");

// Serial.print(accel.acceleration.x);

// Serial.print(" \tY: ");

// Serial.print(accel.acceleration.y);

// Serial.print(" \tZ: ");

// Serial.print(accel.acceleration.z);

// Serial.println(" m/s^2 ");

/* Display the results (rotation is measured in rad/s) */

// Serial.print("\t\tGyro X: ");

// Serial.print(gyro.gyro.x);

// Serial.print(" \tY: ");

// Serial.print(gyro.gyro.y);

// Serial.print(" \tZ: ");

// Serial.print(gyro.gyro.z);

// Serial.println(" radians/s ");

// Serial.println();

if (ble.available()) { // if there is data to be read from the phone serial

String message = ble.readStringUntil('\n'); // reads the message until there is a new line

message.toLowerCase();

if (message == "start monitoring") {

monitor = true; // boolean for flex sensor

ble.println("started");

}

else if (message == "stop monitoring") {

monitor = false;

ble.println("stopped");

}

else if (message == "calibrate flex sensor") {

flexCalibrate = true;

}

else if (message == "do wrist turns") {

ble.println("how many?");

while (!ble.available()) {

delay(100); // delay until there is data to be read from the phone (otherwise the code runs so fast it will skip over the phone input)

Serial.print(".");

}

String str = ble.readStringUntil('\n');

wristTurns = str.toInt();

ble.println(wristTurns);

exercise = true;

}

else if (message == "menu") {

ble.println("1. 'calibrate flex sensor' - calibrates the flex sensor, DO THIS FIRSTTTTTT");

ble.println("2. 'start monitoring' - allows the device to monitor the angle of your wrist and beep if the angle is too steep");

ble.println("3. 'stop monitoring' - the device will stop monitoring the angle of your wrist, mainly used when sleeping");

ble.println("4. 'do wrist turns' - you will be prompted to enter the amount of wrist turns you do and it will monitor how many you do");

}

}

if (flexCalibrate) { // calibrating flex sensor

ble.println("Hold out wrist and keep it straight");

delay(500);

int total = 0;

for (int i = 0; i < 50; i++) {

int value;

value = analogRead(flexPin); // converts the analog voltage to readable digital data

float voltageNumber = value * (3.3/4095.0); // converts the digital data to voltage

float resistance = fixedResistance * (3.3/voltageNumber - 1.0);

Serial.println("Resistance: " + String(resistance));

total += resistance;

ble.println("Getting flex sensor threshold for 0 degrees");

delay(100);

}

map1 = total/50;

total = 0;

ble.println("Nice! Now bend wrist at 40 degrees and hold it");

delay(5000);

for (int i = 0; i < 50; i++) {

int value2;

value2 = analogRead(flexPin); // converts the analog voltage to readable digital data

float voltageNumber2 = value2 * (3.3/4095.0); // converts the digital data to voltage

float resistance2 = fixedResistance * (3.3/voltageNumber2 - 1.0);

Serial.println("Resistance part 2: " + String(resistance2));

ble.println("Getting flex sensor threshold for 40 degrees");

total += resistance2;

delay(100);

}

map2 = total/50;

total = 0;

flexCalibrate = false;

ble.println("Flex sensor calibrated");

ble.println("Map1: " + String(map1));

ble.println("Map2: " + String(map2));

}

if (monitor) { // will start monitoring the angle of the wrist if monitor is true, will not if it's false

int flexValue;

flexValue = analogRead(flexPin); // converts the analog voltage to readable digital data

float voltage = flexValue * (3.3/4095.0); // converts the digital data to voltage

float flexResistance = fixedResistance * (3.3/voltage - 1.0); // converts voltage to resistance

Serial.println(String(flexResistance) + " resistance");

float angle = map(flexResistance, map1, map2, 0.0, 40.0); // converts resistance to angle it's bent at

Serial.println("flexValue: "+ String(flexValue));

Serial.print("angle: ");

Serial.println(String(angle) + " degrees");

if (angle >= 40) {

ble.println("Tilt wrist up");

tone(buzzer, 5000); // piezo buzzer buzzes

for (int i = 0; i < 8; i++) {

ring.setPixelColor(ledPins[i], 255, 0, 0);

ring.show();

}

for (int i = 5; i <= 12 ; i++) {

ring.setPixelColor(i, 0, 255, 0);

ring.show();

}

}

else if (angle <= -5) {

ble.println("Tilt wrist down");

tone(buzzer, 5000);

for (int i = 0; i < 8; i++) {

ring.setPixelColor(ledPins[i], 0, 255, 0);

ring.show();

}

for (int i = 5; i <= 12 ; i++) {

ring.setPixelColor(i, 255, 0, 0);

ring.show();

}

}

else {

noTone(buzzer);

ring.clear();

ring.show();

}

}

else if (calibrated) {

noTone(buzzer);

}

else {

noTone(buzzer);

ring.clear();

ring.show();

}

filter.updateIMU((gyro.gyro.x * 180)/PI,

(gyro.gyro.y * 180)/PI, (gyro.gyro.z * 180)/PI,

accel.acceleration.x, accel.acceleration.y, accel.acceleration.z); // Madgwick filter updates its values

if (repCount < wristTurns && exercise) { // will run if the use wants to do wrist turns

if (!calibrated) { // calibrating

if (filter.getPitch() <= 2 && filter.getPitch() >= -2) {

ble.print("Filter angles: ");

ble.print(filter.getRoll());

ble.print(" ");

ble.print(filter.getYaw());

ble.print(" ");

ble.println(filter.getPitch());

ble.println("Calibrating.....");

ring.setPixelColor(pinCounter, 0, 0, 255);

ring.show();

pinCounter++;

delay(50);

if (pinCounter == ring.numPixels()) {

pinCounter = 0;

ring.clear();

ring.show();

delay(50);

}

countSeconds++;

if (countSeconds == 60) { // if the pitch value of wrist is between 2 and -2 for 3 seconds

calibrated = true;

ble.println("Calibrated! You can begin");

countSeconds = 0;

pinCounter = 0;

ring.clear();

ring.show();

}

}

else {

ble.print("Filter angles: ");

ble.print(filter.getRoll());

ble.print(" ");

ble.print(filter.getYaw());

ble.print(" ");

ble.println(filter.getPitch());

delay(10);

ble.println("Straighten out your wrist");

countSeconds = 0;

}

}

if (calibrated) {

if (filter.getPitch() >= 26) { // if wrist is pointed down and the pitch value exceeds 42

waiting4Raise = true; // boolean for waiting for the wrist to go up

repStart = currentTime; // the starting time of the rep

}

if (waiting4Raise && currentTime - repStart <= 2000) { // if waiting4Raise is true and the time between the current time and the start time is less than 2 seconds

if (filter.getPitch() <= -34) { // if the wrist is pointed up and the pitch value is less than -56

repCount += 1;

tone(buzzer, 3000, 500); // buzz

ring.setPixelColor(pinCounter, 0, 255, 0);

ring.show();

pinCounter++;

if (pinCounter == ring.numPixels()) {

pinCounter = 0;

}

ble.println(repCount);

waiting4Raise = false;

}

}

}

if (repCount == wristTurns) { // the goal has been reached

ble.println("Congrats! You're done!");

repCount = 0;

exercise = false;

calibrated = false;

play();

delay(500);

pinCounter = 0;

rainbow(1);

ring.clear();

ring.show();

}

}

delay(50);

// // serial plotter friendly format

// Serial.print(temp.temperature);

// Serial.print(",");

// Serial.print(accel.acceleration.x);

// Serial.print(","); Serial.print(accel.acceleration.y);

// Serial.print(","); Serial.print(accel.acceleration.z);

// Serial.print(",");

// Serial.print(gyro.gyro.x);

// Serial.print(","); Serial.print(gyro.gyro.y);

// Serial.print(","); Serial.print(gyro.gyro.z);

// Serial.println();

// delayMicroseconds(10000);

}

void rainbow(int wait) {

for(long firstPixelHue = 0; firstPixelHue < 5*65536; firstPixelHue += 256) {

for(int i= 0; i<ring.numPixels(); i++) {

int pixelHue = firstPixelHue + (i * 65536L / ring.numPixels());

ring.setPixelColor(i, ring.gamma32(ring.ColorHSV(pixelHue)));

}

ring.show();

delay(wait);

}

}

void play() {

delay(500);

tone(buzzer, 880, 500); // buzzer indicating that process is done

delay(250);

tone(buzzer, 988, 500);

delay(250);

tone(buzzer, 1046, 500);

delay(250);

tone(buzzer, 1174, 500);

delay(250);

tone(buzzer, 1318, 500);

delay(250);

tone(buzzer, 1396, 500);

delay(250);

tone(buzzer, 1568, 500);

delay(250);

tone(buzzer, 1760, 500);

}

Third Milestone

// Basic demo for accelerometer/gyro readings from Adafruit LSM6DS3TR-C

const int flexPin = A6;

const int fixedResistance = 10000;

const int buzzer = 18;

unsigned long currentTime = millis();

unsigned long repStart = 0.0;

int repCount = 0;

int wristTurns = 1;

int countSeconds = 0;

bool waiting4Raise = false;

bool calibrated = false;

bool monitor = false;

bool exercise = false;

#include <MadgwickAHRS.h>

#include <Adafruit_LSM6DS3TRC.h>

#include <BleSerial.h>

// For SPI mode, we need a CS pin

#define LSM_CS 10

// For software-SPI mode we need SCK/MOSI/MISO pins

#define LSM_SCK 13

#define LSM_MISO 12

#define LSM_MOSI 11

Adafruit_LSM6DS3TRC lsm6ds3trc;

Madgwick filter;

BleSerial ble;

const float sampleFreq = 20.0;

void setup() {

Serial.begin(115200);

filter.begin(sampleFreq);

ble.begin("danica's serial");

while (!Serial)

delay(10); // will pause Zero, Leonardo, etc until serial console opens

Serial.println("Adafruit LSM6DS3TR-C test!");

if (!lsm6ds3trc.begin_I2C()) {

// if (!lsm6ds3trc.begin_SPI(LSM_CS)) {

// if (!lsm6ds3trc.begin_SPI(LSM_CS, LSM_SCK, LSM_MISO, LSM_MOSI)) {

Serial.println("Failed to find LSM6DS3TR-C chip");

while (1) {

delay(10);

}

}

Serial.println("LSM6DS3TR-C Found!");

// lsm6ds3trc.setAccelRange(LSM6DS_ACCEL_RANGE_2_G);

Serial.print("Accelerometer range set to: ");

switch (lsm6ds3trc.getAccelRange()) {

case LSM6DS_ACCEL_RANGE_2_G:

Serial.println("+-2G");

break;

case LSM6DS_ACCEL_RANGE_4_G:

Serial.println("+-4G");

break;

case LSM6DS_ACCEL_RANGE_8_G:

Serial.println("+-8G");

break;

case LSM6DS_ACCEL_RANGE_16_G:

Serial.println("+-16G");

break;

}

// lsm6ds3trc.setGyroRange(LSM6DS_GYRO_RANGE_250_DPS);

Serial.print("Gyro range set to: ");

switch (lsm6ds3trc.getGyroRange()) {

case LSM6DS_GYRO_RANGE_125_DPS:

Serial.println("125 degrees/s");

break;

case LSM6DS_GYRO_RANGE_250_DPS:

Serial.println("250 degrees/s");

break;

case LSM6DS_GYRO_RANGE_500_DPS:

Serial.println("500 degrees/s");

break;

case LSM6DS_GYRO_RANGE_1000_DPS:

Serial.println("1000 degrees/s");

break;

case LSM6DS_GYRO_RANGE_2000_DPS:

Serial.println("2000 degrees/s");

break;

case ISM330DHCX_GYRO_RANGE_4000_DPS:

break; // unsupported range for the DS33

}

//lsm6ds3trc.setAccelDataRate(LSM6DS_RATE_20_HZ);

Serial.print("Accelerometer data rate set to: ");

switch (lsm6ds3trc.getAccelDataRate()) {

case LSM6DS_RATE_SHUTDOWN:

Serial.println("0 Hz");

break;

case LSM6DS_RATE_12_5_HZ:

Serial.println("12.5 Hz");

break;

case LSM6DS_RATE_26_HZ:

Serial.println("26 Hz");

break;

case LSM6DS_RATE_52_HZ:

Serial.println("52 Hz");

break;

case LSM6DS_RATE_104_HZ:

Serial.println("104 Hz");

break;

case LSM6DS_RATE_208_HZ:

Serial.println("208 Hz");

break;

case LSM6DS_RATE_416_HZ:

Serial.println("416 Hz");

break;

case LSM6DS_RATE_833_HZ:

Serial.println("833 Hz");

break;

case LSM6DS_RATE_1_66K_HZ:

Serial.println("1.66 KHz");

break;

case LSM6DS_RATE_3_33K_HZ:

Serial.println("3.33 KHz");

break;

case LSM6DS_RATE_6_66K_HZ:

Serial.println("6.66 KHz");

break;

}

// lsm6ds3trc.setGyroDataRate(LSM6DS_RATE_12_5_HZ);

Serial.print("Gyro data rate set to: ");

switch (lsm6ds3trc.getGyroDataRate()) {

case LSM6DS_RATE_SHUTDOWN:

Serial.println("0 Hz");

break;

case LSM6DS_RATE_12_5_HZ:

Serial.println("12.5 Hz");

break;

case LSM6DS_RATE_26_HZ:

Serial.println("26 Hz");

break;

case LSM6DS_RATE_52_HZ:

Serial.println("52 Hz");

break;

case LSM6DS_RATE_104_HZ:

Serial.println("104 Hz");

break;

case LSM6DS_RATE_208_HZ:

Serial.println("208 Hz");

break;

case LSM6DS_RATE_416_HZ:

Serial.println("416 Hz");

break;

case LSM6DS_RATE_833_HZ:

Serial.println("833 Hz");

break;

case LSM6DS_RATE_1_66K_HZ:

Serial.println("1.66 KHz");

break;

case LSM6DS_RATE_3_33K_HZ:

Serial.println("3.33 KHz");

break;

case LSM6DS_RATE_6_66K_HZ:

Serial.println("6.66 KHz");

break;

}

lsm6ds3trc.configInt1(false, false, true); // accelerometer DRDY on INT1

lsm6ds3trc.configInt2(false, true, false); // gyro DRDY on INT2

pinMode(buzzer, OUTPUT);

}

void loop() {

// Get a new normalized sensor event

sensors_event_t accel;

sensors_event_t gyro;

sensors_event_t temp;

lsm6ds3trc.getEvent(&accel, &gyro, &temp);

// Serial.print("\t\tTemperature ");

// Serial.print(temp.temperature);

// Serial.println(" deg C");

/* Display the results (acceleration is measured in m/s^2) */

// Serial.print("\t\tAccel X: ");

// Serial.print(accel.acceleration.x);

// Serial.print(" \tY: ");

// Serial.print(accel.acceleration.y);

// Serial.print(" \tZ: ");

// Serial.print(accel.acceleration.z);

// Serial.println(" m/s^2 ");

/* Display the results (rotation is measured in rad/s) */

// Serial.print("\t\tGyro X: ");

// Serial.print(gyro.gyro.x);

// Serial.print(" \tY: ");

// Serial.print(gyro.gyro.y);

// Serial.print(" \tZ: ");

// Serial.print(gyro.gyro.z);

// Serial.println(" radians/s ");

// Serial.println();

if (ble.available()) { // if there is data to be read from the phone serial

String message = ble.readStringUntil('\n'); // reads the message until there is a new line

message.toLowerCase();

if (message == "start monitoring") {

monitor = true; // boolean for flex sensor

ble.println("started");

}

else if (message == "stop monitoring") {

monitor = false;

ble.println("stopped");

}

else if (message == "do wrist turns") {

ble.println("how many?");

while (!ble.available()) {

delay(100); // delay until there is data to be read from the phone (otherwise the code runs so fast it will skip over the phone input)

Serial.print(".");

}

String str = ble.readStringUntil('\n');

ble.println(str);

wristTurns = str.toInt();

Serial.println(wristTurns);

exercise = true;

}

else if (message == "menu") {

ble.println("1. 'start monitoring' - allows the device to monitor the angle of your wrist and beep if the angle is too steep");

ble.println("2. 'stop monitoring' - the device will stop monitoring the angle of your wrist, mainly used when sleeping");

ble.println("3. 'do wrist turns' - you will be prompted to enter the amount of wrist turns you do and it will monitor how many you do");

}

}

if (monitor) { // will start monitoring the angle of the wrist if monitor is true, will not if it's false

int flexValue;

flexValue = analogRead(flexPin); // converts the analog voltage to readable digital data

float voltage = flexValue * (3.3/4095.0); // converts the digital data to voltage

float flexResistance = fixedResistance * (3.3/voltage - 1.0); // converts voltage to resistance

Serial.println(String(flexResistance) + " resistance");

float angle = map(flexResistance, 15000, 45000, 0.0, 90.0); // converts resistance to angle it's bent at

Serial.println("flexValue: "+ String(flexValue));

Serial.print("angle: ");

Serial.println(String(angle) + " degrees");

if (angle >= 21) {

ble.println("Tilt wrist up");

tone(buzzer, 5000); // piezo buzzer buzzes

}

else if(angle <= -7) {

ble.println("Tilt wrist down");

tone(buzzer, 5000);

}

else {

noTone(buzzer);

}

}

else {

noTone(buzzer);

}

filter.updateIMU((gyro.gyro.x * 180)/PI,

(gyro.gyro.y * 180)/PI, (gyro.gyro.z * 180)/PI,

accel.acceleration.x, accel.acceleration.y, accel.acceleration.z); // Madgwick filter updates its values

if (repCount < wristTurns && exercise) { // will run if the use wants to do wrist turns

if (!calibrated) { // calibrating

if (filter.getPitch() <= 2 && filter.getPitch() >= -2) {

Serial.print("Filter angles: ");

Serial.print(filter.getRoll());

Serial.print(" ");

Serial.print(filter.getYaw());

Serial.print(" ");

Serial.println(filter.getPitch());

ble.println("Calibrating.....");

countSeconds++;

if (countSeconds == 60) { // if the pitch value of wrist is between 2 and -2 for 3 seconds

calibrated = true;

ble.println("Calibrated! You can begin");

countSeconds = 0;

}

}

else {

Serial.print("Filter angles: ");

Serial.print(filter.getRoll());

Serial.print(" ");

Serial.print(filter.getYaw());

Serial.print(" ");

Serial.println(filter.getPitch());

ble.println("Straighten out your wrist");

countSeconds = 0;

}

}

if (calibrated) {

if (filter.getPitch() >= 42) { // if wrist is pointed down and the pitch value exceeds 42

waiting4Raise = true; // boolean for waiting for the wrist to go up

repStart = currentTime; // the starting time of the rep

}

if (waiting4Raise && currentTime - repStart <= 2000) { // if waiting4Raise is true and the time between the current time and the start time is less than 2 seconds

if (filter.getPitch() <= -56) { // if the wrist is pointed up and the pitch value is less than -56

repCount += 1;

tone(buzzer, 3000, 500); // buzz

ble.println(repCount);

waiting4Raise = false;

}

}

}

if (repCount == wristTurns) { // the goal has been reached

ble.println("Congrats! You're done!");

repCount = 0;

exercise = false;

calibrated = false;

tone(buzzer, 4000, 500); // buzzer indicating that process is done

delay(1000);

tone(buzzer, 4000, 500);

delay(1000);

tone(buzzer, 4000, 500);

}

}

delay(50);

// // serial plotter friendly format

// Serial.print(temp.temperature);

// Serial.print(",");

// Serial.print(accel.acceleration.x);

// Serial.print(","); Serial.print(accel.acceleration.y);

// Serial.print(","); Serial.print(accel.acceleration.z);

// Serial.print(",");

// Serial.print(gyro.gyro.x);

// Serial.print(","); Serial.print(gyro.gyro.y);

// Serial.print(","); Serial.print(gyro.gyro.z);

// Serial.println();

// delayMicroseconds(10000);

}

Second Milestone

// Basic demo for accelerometer/gyro readings from Adafruit LSM6DS3TR-C

const int flexPin = A6;

const int fixedResistance = 10000;

const int buzzer = 18;

unsigned long currentTime = millis();

unsigned long repStart = 0.0;

int repCount = 0;

int wristTurns = 1;

int countSeconds = 0;

bool waiting4Raise = false;

bool calibrated = false;

bool monitor = false;

bool exercise = false;

#include <MadgwickAHRS.h>

#include <Adafruit_LSM6DS3TRC.h>

#include <BleSerial.h>

// For SPI mode, we need a CS pin

#define LSM_CS 10

// For software-SPI mode we need SCK/MOSI/MISO pins

#define LSM_SCK 13

#define LSM_MISO 12

#define LSM_MOSI 11

Adafruit_LSM6DS3TRC lsm6ds3trc;

Madgwick filter;

BleSerial ble;

const float sampleFreq = 20.0;

void setup() {

Serial.begin(115200);

filter.begin(sampleFreq);

ble.begin("danica's serial");

while (!Serial)

delay(10); // will pause Zero, Leonardo, etc until serial console opens

Serial.println("Adafruit LSM6DS3TR-C test!");

if (!lsm6ds3trc.begin_I2C()) {

// if (!lsm6ds3trc.begin_SPI(LSM_CS)) {

// if (!lsm6ds3trc.begin_SPI(LSM_CS, LSM_SCK, LSM_MISO, LSM_MOSI)) {

Serial.println("Failed to find LSM6DS3TR-C chip");

while (1) {

delay(10);

}

}

Serial.println("LSM6DS3TR-C Found!");

// lsm6ds3trc.setAccelRange(LSM6DS_ACCEL_RANGE_2_G);

Serial.print("Accelerometer range set to: ");

switch (lsm6ds3trc.getAccelRange()) {

case LSM6DS_ACCEL_RANGE_2_G:

Serial.println("+-2G");

break;

case LSM6DS_ACCEL_RANGE_4_G:

Serial.println("+-4G");

break;

case LSM6DS_ACCEL_RANGE_8_G:

Serial.println("+-8G");

break;

case LSM6DS_ACCEL_RANGE_16_G:

Serial.println("+-16G");

break;

}

// lsm6ds3trc.setGyroRange(LSM6DS_GYRO_RANGE_250_DPS);

Serial.print("Gyro range set to: ");

switch (lsm6ds3trc.getGyroRange()) {

case LSM6DS_GYRO_RANGE_125_DPS:

Serial.println("125 degrees/s");

break;

case LSM6DS_GYRO_RANGE_250_DPS:

Serial.println("250 degrees/s");

break;

case LSM6DS_GYRO_RANGE_500_DPS:

Serial.println("500 degrees/s");

break;

case LSM6DS_GYRO_RANGE_1000_DPS:

Serial.println("1000 degrees/s");

break;

case LSM6DS_GYRO_RANGE_2000_DPS:

Serial.println("2000 degrees/s");

break;

case ISM330DHCX_GYRO_RANGE_4000_DPS:

break; // unsupported range for the DS33

}

//lsm6ds3trc.setAccelDataRate(LSM6DS_RATE_20_HZ);

Serial.print("Accelerometer data rate set to: ");

switch (lsm6ds3trc.getAccelDataRate()) {

case LSM6DS_RATE_SHUTDOWN:

Serial.println("0 Hz");

break;

case LSM6DS_RATE_12_5_HZ:

Serial.println("12.5 Hz");

break;

case LSM6DS_RATE_26_HZ:

Serial.println("26 Hz");

break;

case LSM6DS_RATE_52_HZ:

Serial.println("52 Hz");

break;

case LSM6DS_RATE_104_HZ:

Serial.println("104 Hz");

break;

case LSM6DS_RATE_208_HZ:

Serial.println("208 Hz");

break;

case LSM6DS_RATE_416_HZ:

Serial.println("416 Hz");

break;

case LSM6DS_RATE_833_HZ:

Serial.println("833 Hz");

break;

case LSM6DS_RATE_1_66K_HZ:

Serial.println("1.66 KHz");

break;

case LSM6DS_RATE_3_33K_HZ:

Serial.println("3.33 KHz");

break;

case LSM6DS_RATE_6_66K_HZ:

Serial.println("6.66 KHz");

break;

}

// lsm6ds3trc.setGyroDataRate(LSM6DS_RATE_12_5_HZ);

Serial.print("Gyro data rate set to: ");

switch (lsm6ds3trc.getGyroDataRate()) {

case LSM6DS_RATE_SHUTDOWN:

Serial.println("0 Hz");

break;

case LSM6DS_RATE_12_5_HZ:

Serial.println("12.5 Hz");

break;

case LSM6DS_RATE_26_HZ:

Serial.println("26 Hz");

break;

case LSM6DS_RATE_52_HZ:

Serial.println("52 Hz");

break;

case LSM6DS_RATE_104_HZ:

Serial.println("104 Hz");

break;

case LSM6DS_RATE_208_HZ:

Serial.println("208 Hz");

break;

case LSM6DS_RATE_416_HZ:

Serial.println("416 Hz");

break;

case LSM6DS_RATE_833_HZ:

Serial.println("833 Hz");

break;

case LSM6DS_RATE_1_66K_HZ:

Serial.println("1.66 KHz");

break;

case LSM6DS_RATE_3_33K_HZ:

Serial.println("3.33 KHz");

break;

case LSM6DS_RATE_6_66K_HZ:

Serial.println("6.66 KHz");

break;

}

lsm6ds3trc.configInt1(false, false, true); // accelerometer DRDY on INT1

lsm6ds3trc.configInt2(false, true, false); // gyro DRDY on INT2

pinMode(buzzer, OUTPUT);

}

void loop() {

// Get a new normalized sensor event

sensors_event_t accel;

sensors_event_t gyro;

sensors_event_t temp;

lsm6ds3trc.getEvent(&accel, &gyro, &temp);

// Serial.print("\t\tTemperature ");

// Serial.print(temp.temperature);

// Serial.println(" deg C");

/* Display the results (acceleration is measured in m/s^2) */

// Serial.print("\t\tAccel X: ");

// Serial.print(accel.acceleration.x);

// Serial.print(" \tY: ");

// Serial.print(accel.acceleration.y);

// Serial.print(" \tZ: ");

// Serial.print(accel.acceleration.z);

// Serial.println(" m/s^2 ");

/* Display the results (rotation is measured in rad/s) */

// Serial.print("\t\tGyro X: ");

// Serial.print(gyro.gyro.x);

// Serial.print(" \tY: ");

// Serial.print(gyro.gyro.y);

// Serial.print(" \tZ: ");

// Serial.print(gyro.gyro.z);

// Serial.println(" radians/s ");

// Serial.println();

// if there is data to be read from the phone serial

if (ble.available()) {

// reads the message until there is a new line

String message = ble.readStringUntil('\n');

message.toLowerCase();

if (message == "start monitoring") {

monitor = true;

ble.println("started");

}

else if (message == "stop monitoring") {

monitor = false;

ble.println("stopped");

}

else if (message == "do wrist turns") {

ble.println("how many?");

while (!ble.available()) {

// delay until there is data to be read from the phone (otherwise the code runs so fast it will skip over the phone input)

delay(100);

Serial.print(".");

}

String str = ble.readStringUntil('\n');

ble.println(str);

wristTurns = str.toInt();

Serial.println(wristTurns);

exercise = true;

}

else if (message == "menu") {

ble.println("1. 'start monitoring' - allows the device to monitor the angle of your wrist and beep if the angle is too steep");

ble.println("2. 'stop monitoring' - the device will stop monitoring the angle of your wrist, mainly used when sleeping");

ble.println("3. 'do wrist turns' - you will be prompted to enter the amount of wrist turns you do and it will monitor how many you do");

}

}

// will start monitoring the angle of the wrist if monitor is true, will not if it's false

if (monitor) {

int flexValue;

// converts the analog voltage to readable digital data

flexValue = analogRead(flexPin);

// converts the digital data to voltage

float voltage = flexValue * (3.3/4095.0);

// converts voltage to resistance

float flexResistance = fixedResistance * (3.3/voltage - 1.0);

// converts resistance to angle it's bent at

float angle = map(flexResistance, 12000, 28000, 0.0, 90.0);

Serial.print("angle: ");

Serial.println(String(angle) + " degrees");

if (angle > 30 || angle < -5) {

ble.println("fix posture");

// piezo buzzer buzzes

tone(buzzer, 1000);

}

else {

noTone(buzzer);

}

}

// Madgwick filter updates its values

filter.updateIMU((gyro.gyro.x * 180)/PI, (gyro.gyro.y * 180)/PI, (gyro.gyro.z * 180)/PI, accel.acceleration.x, accel.acceleration.y, accel.acceleration.z);

// will run if the use wants to do wrist turns

if (repCount < wristTurns && exercise) {

// calibrating

if (!calibrated) {

if (filter.getPitch() <= 2 && filter.getPitch() >= -2) {

Serial.print("Filter angles: ");

Serial.print(filter.getRoll());

Serial.print(" ");

Serial.print(filter.getYaw());

Serial.print(" ");

Serial.println(filter.getPitch());

ble.println("Calibrating.....");

countSeconds++;

// if the pitch value of wrist is between 2 and -2 for 3 seconds

if (countSeconds == 60) {

calibrated = true;

ble.println("Calibrated! You can begin");

countSeconds = 0;

}

}

else {

Serial.print("Filter angles: ");

Serial.print(filter.getRoll());

Serial.print(" ");

Serial.print(filter.getYaw());

Serial.print(" ");

Serial.println(filter.getPitch());

ble.println("Straighten out your wrist");

countSeconds = 0;

}

}

if (calibrated) {

// if wrist is pointed down and the pitch value exceeds 42

if (filter.getPitch() >= 42) {

// boolean for waiting for the wrist to go up

waiting4Raise = true;

// the starting time of the rep

repStart = currentTime;

}

// if waiting4Raise is true and the time between the current time and the start time is less than 2 seconds

if (waiting4Raise && currentTime - repStart <= 2000) {

// if the wrist is pointed up and the pitch value is less than -56

if (filter.getPitch() <= -56) {

repCount += 1;

// buzz

tone(buzzer, 3000, 500);

ble.println(repCount);

waiting4Raise = false;

}

}

}

// the goal has been reached

if (repCount == wristTurns) {

ble.println("Congrats! You're done!");

repCount = 0;

exercise = false;

calibrated = false;

// buzzer indicating that it's done

tone(buzzer, 4000, 500);

delay(1200);

tone(buzzer, 4000, 500);

delay(1200);

tone(buzzer, 4000, 500);

}

}

delay(50);

// // serial plotter friendly format

// Serial.print(temp.temperature);

// Serial.print(",");

// Serial.print(accel.acceleration.x);

// Serial.print(","); Serial.print(accel.acceleration.y);

// Serial.print(","); Serial.print(accel.acceleration.z);

// Serial.print(",");

// Serial.print(gyro.gyro.x);

// Serial.print(","); Serial.print(gyro.gyro.y);

// Serial.print(","); Serial.print(gyro.gyro.z);

// Serial.println();

// delayMicroseconds(10000);

}

First Milestone

// Basic demo for accelerometer/gyro readings from Adafruit LSM6DS3TR-C

const int flexPin = A6;

const int fixedResistance = 10000;

#include <MadgwickAHRS.h>

#include <Adafruit_LSM6DS3TRC.h>

// For SPI mode, we need a CS pin

#define LSM_CS 10

// For software-SPI mode we need SCK/MOSI/MISO pins

#define LSM_SCK 13

#define LSM_MISO 12

#define LSM_MOSI 11

Adafruit_LSM6DS3TRC lsm6ds3trc;

Madgwick filter;

void setup(void) {

Serial.begin(115200);

filter.begin(10);

while (!Serial)

delay(10); // will pause Zero, Leonardo, etc until serial console opens

Serial.println("Adafruit LSM6DS3TR-C test!");

if (!lsm6ds3trc.begin_I2C()) {

// if (!lsm6ds3trc.begin_SPI(LSM_CS)) {

// if (!lsm6ds3trc.begin_SPI(LSM_CS, LSM_SCK, LSM_MISO, LSM_MOSI)) {

Serial.println("Failed to find LSM6DS3TR-C chip");

while (1) {

delay(10);

}

}

Serial.println("LSM6DS3TR-C Found!");

// lsm6ds3trc.setAccelRange(LSM6DS_ACCEL_RANGE_2_G);

Serial.print("Accelerometer range set to: ");

switch (lsm6ds3trc.getAccelRange()) {

case LSM6DS_ACCEL_RANGE_2_G:

Serial.println("+-2G");

break;

case LSM6DS_ACCEL_RANGE_4_G:

Serial.println("+-4G");

break;

case LSM6DS_ACCEL_RANGE_8_G:

Serial.println("+-8G");

break;

case LSM6DS_ACCEL_RANGE_16_G:

Serial.println("+-16G");

break;

}

// lsm6ds3trc.setGyroRange(LSM6DS_GYRO_RANGE_250_DPS);

Serial.print("Gyro range set to: ");

switch (lsm6ds3trc.getGyroRange()) {

case LSM6DS_GYRO_RANGE_125_DPS:

Serial.println("125 degrees/s");

break;

case LSM6DS_GYRO_RANGE_250_DPS:

Serial.println("250 degrees/s");

break;

case LSM6DS_GYRO_RANGE_500_DPS:

Serial.println("500 degrees/s");

break;

case LSM6DS_GYRO_RANGE_1000_DPS:

Serial.println("1000 degrees/s");

break;

case LSM6DS_GYRO_RANGE_2000_DPS:

Serial.println("2000 degrees/s");

break;

case ISM330DHCX_GYRO_RANGE_4000_DPS:

break; // unsupported range for the DS33

}

// lsm6ds3trc.setAccelDataRate(LSM6DS_RATE_12_5_HZ);

Serial.print("Accelerometer data rate set to: ");

switch (lsm6ds3trc.getAccelDataRate()) {

case LSM6DS_RATE_SHUTDOWN:

Serial.println("0 Hz");

break;

case LSM6DS_RATE_12_5_HZ:

Serial.println("12.5 Hz");

break;

case LSM6DS_RATE_26_HZ:

Serial.println("26 Hz");

break;

case LSM6DS_RATE_52_HZ:

Serial.println("52 Hz");

break;

case LSM6DS_RATE_104_HZ:

Serial.println("104 Hz");

break;

case LSM6DS_RATE_208_HZ:

Serial.println("208 Hz");

break;

case LSM6DS_RATE_416_HZ:

Serial.println("416 Hz");

break;

case LSM6DS_RATE_833_HZ:

Serial.println("833 Hz");

break;

case LSM6DS_RATE_1_66K_HZ:

Serial.println("1.66 KHz");

break;

case LSM6DS_RATE_3_33K_HZ:

Serial.println("3.33 KHz");

break;

case LSM6DS_RATE_6_66K_HZ:

Serial.println("6.66 KHz");

break;

}

// lsm6ds3trc.setGyroDataRate(LSM6DS_RATE_12_5_HZ);

Serial.print("Gyro data rate set to: ");

switch (lsm6ds3trc.getGyroDataRate()) {

case LSM6DS_RATE_SHUTDOWN:

Serial.println("0 Hz");

break;

case LSM6DS_RATE_12_5_HZ:

Serial.println("12.5 Hz");

break;

case LSM6DS_RATE_26_HZ:

Serial.println("26 Hz");

break;

case LSM6DS_RATE_52_HZ:

Serial.println("52 Hz");

break;

case LSM6DS_RATE_104_HZ:

Serial.println("104 Hz");

break;

case LSM6DS_RATE_208_HZ:

Serial.println("208 Hz");

break;

case LSM6DS_RATE_416_HZ:

Serial.println("416 Hz");

break;

case LSM6DS_RATE_833_HZ:

Serial.println("833 Hz");

break;

case LSM6DS_RATE_1_66K_HZ:

Serial.println("1.66 KHz");

break;

case LSM6DS_RATE_3_33K_HZ:

Serial.println("3.33 KHz");

break;

case LSM6DS_RATE_6_66K_HZ:

Serial.println("6.66 KHz");

break;

}

lsm6ds3trc.configInt1(false, false, true); // accelerometer DRDY on INT1

lsm6ds3trc.configInt2(false, true, false); // gyro DRDY on INT2

}

void loop() {

// Get a new normalized sensor event

sensors_event_t accel;

sensors_event_t gyro;

sensors_event_t temp;

lsm6ds3trc.getEvent(&accel, &gyro, &temp);

// Serial.print("\t\tTemperature ");

// Serial.print(temp.temperature);

// Serial.println(" deg C");

// /* Display the results (acceleration is measured in m/s^2) */

// Serial.print("\t\tAccel X: ");

// Serial.print(accel.acceleration.x);

// Serial.print(" \tY: ");

// Serial.print(accel.acceleration.y);

// Serial.print(" \tZ: ");

// Serial.print(accel.acceleration.z);

// Serial.println(" m/s^2 ");

// /* Display the results (rotation is measured in rad/s) */

// Serial.print("\t\tGyro X: ");

// Serial.print(gyro.gyro.x);

// Serial.print(" \tY: ");

// Serial.print(gyro.gyro.y);

// Serial.print(" \tZ: ");

// Serial.print(gyro.gyro.z);

// Serial.println(" radians/s ");

// Serial.println();

int flexValue;

flexValue = analogRead(flexPin);

float voltage = flexValue * (3.3/4095.0);

float flexResistance = fixedResistance * (3.3/voltage - 1.0);

//Serial.println(flexResistance);

float angle = map(flexResistance, 12000, 28000, 0.0, 90.0);

Serial.print("angle: ");

Serial.println(String(angle) + " degrees");

filter.updateIMU(gyro.gyro.x, gyro.gyro.y, gyro.gyro.z, accel.acceleration.x, accel.acceleration.y, accel.acceleration.z);

Serial.print("Filter angles: ");

Serial.print(filter.getRoll());

Serial.print(" ");

Serial.print(filter.getYaw());

Serial.print(" ");

Serial.println(filter.getPitch());

if (filter.getPitch() < -35 || filter.getPitch() > 30 || angle > 30 || angle < -5) {

Serial.println("fix posture");

}

delay(100);

// // serial plotter friendly format

// Serial.print(temp.temperature);

// Serial.print(",");

// Serial.print(accel.acceleration.x);

// Serial.print(","); Serial.print(accel.acceleration.y);

// Serial.print(","); Serial.print(accel.acceleration.z);

// Serial.print(",");

// Serial.print(gyro.gyro.x);

// Serial.print(","); Serial.print(gyro.gyro.y);

// Serial.print(","); Serial.print(gyro.gyro.z);

// Serial.println();

// delayMicroseconds(10000);

}

Starter Project

Description

For my starter project, I decided to make the RGB slider, which is a small board with sliders and an LED light. Based on which slider I turn up, the LED at the top of the board will turn that color. To make it, I had solder on the sliders, LED light, and the USB-C port. In total I had to solder 29 joints to make sure currents would flow properly. How it works is that the sliders are all resistors, and when they are turned down the resistance is high enough as to not allow any current to pass through. But, once they are turned up the resistance of the sliders decrease, hence allowing the current to pass through and light up the LED.

Challenges

One of the challenges I had was that I accidentally soldered one of the holes wrong, so I had to use a pump to desolder the metal. I almost burned myself in the process. The other challenge I had was that I didn’t know I had to use a specific USB-C cable that only passes one voltage through. The ones I used usually negotiate with the receiver about which voltage to pass though and the receiver will adjust with what it gets. But, since the RGB doesn’t adjust the voltage it gets, the cable got confused on how much voltage to give it. I also had tried using my computer as the power generator, but it also didn’t know how much voltage to pass through the board. Eventually I used a cable that only passed one voltage through and it worked fine.

Next Steps

For my next project, I will begin working on my wrist rehabilitation device using the skills I learned from my starter project.

Bill of Materials

| Part | Note | Price | Link |

|---|---|---|---|

| ESP32-WROOM-32D | The microcontroller that has a built in Bluetooth module and that all of the sensors connect to | $9.99 | Link |

| Piezo Buzzer | The buzzer that beeps to alert wrong form and when doing wrist turns | $7.28 | Link |

| Flex Sensor (4.5”) | Used to measure the angle of wrist | $24.95 | Link |

| Adafruit LSM6DS3TR-C + LIS3MDL - Precision 9 DoF IMU | The device that measures both accelerometer and gyroscope values | $19.95 | Link |

| Adafruit 16 Bit Neopixel LED Ring | The LED ring that lights up when the wrist is too bent and when doing wrist turns | $8.68 | Link |

| Wrist Compression Sleeve | The wrist sleeve that all the sensors and PCB board rest on | $15.97 | Link |